- 您现在的位置:买卖IC网 > Sheet目录442 > IR383 (Everlight Electronics Co Ltd)LED IR 5MM GAA1AS BLUE TH

�� �

�

�

�DATASHEET�

�5.0mm� Infrared� LED�

�IR383�

�Notes�

�1.�

�Lead� Forming�

�?�

�?�

�?�

�?�

�?�

�During� lead� formation,� the� leads� should� be� bent� at� a� point� at� least� 3mm� from� the� base� of� the� epoxy� bulb.�

�Lead� forming� should� be� done� before� soldering.�

�Avoid� stressing� the� LED� package� during� leads� forming.� The� stress� to� the� base� may� damage� the� LED’s� characteristics� or� it�

�may� break� the� LEDs.�

�Cut� the� LED� lead� frames� at� room� temperature.� Cutting� the� lead� frames� at� high� temperatures� may� cause� failure� of� the� LEDs.�

�When� mounting� the� LEDs� onto� a� PCB,� the� PCB� holes� must� be� aligned� exactly� with� the� lead� position� of� the� LED.� If� the� LEDs�

�are� mounted� with� stress� at� the� leads,� it� causes� deterioration� of� the� epoxy� resin� and� this� will� degrade� the� LEDs.�

�2.�

�Storage�

�?�

�?�

�The� LEDs� should� be� stored� at� 30°C� or� less� and� 70%RH� or� less� after� being� shipped� from� Everlight� and� the� storage� life� limits�

�are� 3� months.� If� the� LEDs� are� stored� for� 3� months� or� more,� they� can� be� stored� for� a� year� in� a� sealed� container� with� a�

�nitrogen� atmosphere� and� moisture� absorbent� material.�

�Please� avoid� rapid� transitions� in� ambient� temperature,� especially,� in� high� humidity� environments� where� condensation� can�

�occur.�

�3.�

�Soldering�

�?�

�?�

�Careful� attention� should� be� paid� during� soldering.� When� soldering,� leave� more� then� 3mm� from� solder� joint� to� epoxy� bulb,�

�and� soldering� beyond� the� base� of� the� tie� bar� is� recommended.�

�Recommended� soldering� conditions:�

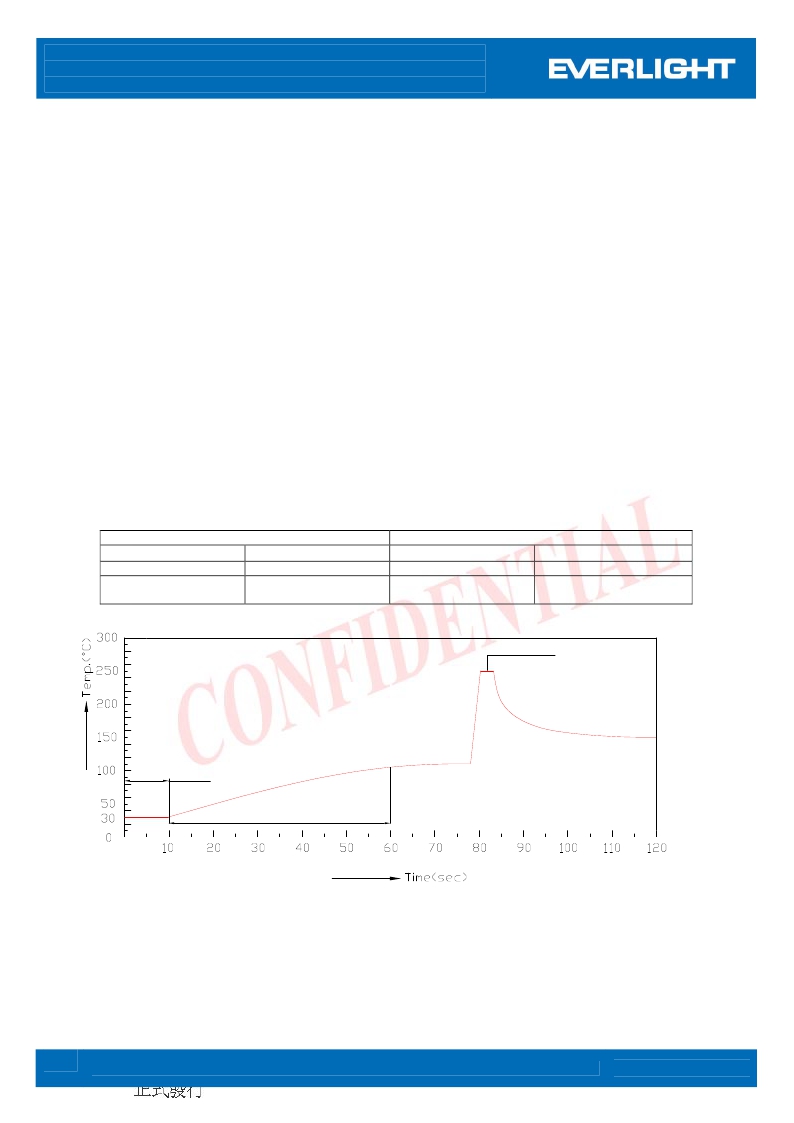

�Hand� Soldering�

�DIP� Soldering�

�Temp.� at� tip� of� iron�

�Soldering� time�

�Distance�

�300� ℃� Max.� (30W� Max.)�

�3� sec� Max.�

�3mm� Min.(From� solder�

�joint� to� epoxy� bulb)�

�Preheat� temp.�

�Bath� temp.� &� time�

�Distance�

�100� ℃� Max.� (60� sec� Max.)�

�260� Max.,� 5� sec� Max�

�3mm� Min.� (From� solder�

�joint� to� epoxy� bulb)�

�?�

�?�

�?�

�?�

�?�

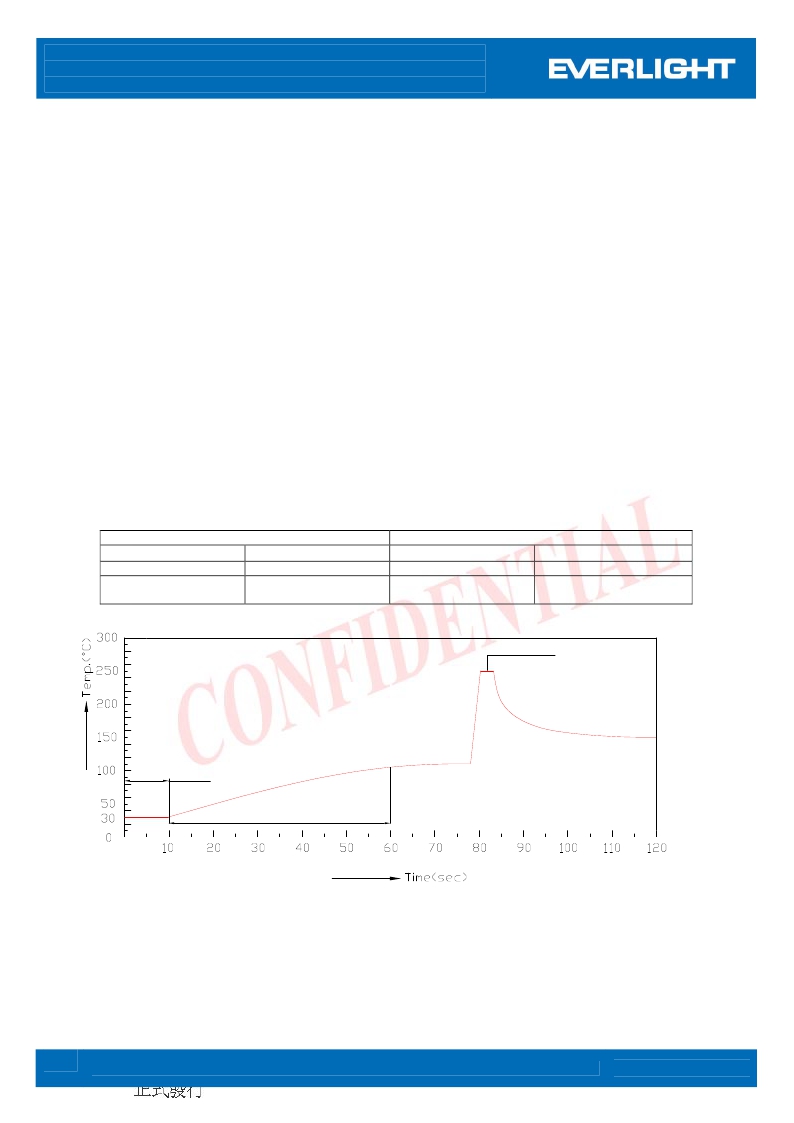

�Recommended� soldering� profile�

�laminar� wave�

�Fluxing�

�Prehead�

�Avoiding� applying� any� stress� to� the� lead� frame� while� the� LEDs� are� at� high� temperature� particularly� when� soldering.�

�Dip� and� hand� soldering� should� not� be� done� more� than� one� time�

�After� soldering� the� LEDs,� the� epoxy� bulb� should� be� protected� from� mechanical� shock� or� vibration� until� the� LEDs� return� to�

�room� temperature.�

�A� rapid-rate� process� is� not� recommended� for� cooling� the� LEDs� down� from� the� peak� temperature.�

�7�

�:� (3)�

�Revision� Copyright� ?�

�No:� Release Date:�

�2010,� Everlight� All� Rights� Reserved.� Release� Date� :� JUL.10.2013.� Issue� DIR-0000988�

�www.everlight.com�

�LifecyclePhase:�

�Expired� Period:� Forever�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

IR42-21C/TR8

LED IR SUBMINI 1.8MM ROUND SMD

IR533C

LED IR SMD GAA1AS WATER CLEAR

IR67-21C/TR8

LED IR TOP GAA1AS WATER CLR SMD

IR7373C

LED IR 5MM GAA1AS WATER CLEAR

IR7393C

LED IR 5MM GAA1AS WATER CLEAR

IR908-7C-F

LED IR 1.5MM SIDE FACE WATER CLR

IR91-21C/TR10

LED IR 1.9MM ROUND SUBMINI ZBEND

IR91-21C/TR7

LED IR 1.9MM RND SUBMINI GULLWIN

相关代理商/技术参数

IR3831MPBF

制造商:IRF 制造商全称:International Rectifier 功能描述:HIGHLY EFFICIENT INTEGRATED SYNCHRONOUS BUCK REGULATOR FOR DDR APPLICATIONS

IR3831MTR1PBF

功能描述:直流/直流开关调节器 8A SupIRBuck Reg 250-1500kHz, 1.5-16V

RoHS:否 制造商:International Rectifier 最大输入电压:21 V 开关频率:1.5 MHz 输出电压:0.5 V to 0.86 V 输出电流:4 A 输出端数量: 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:PQFN 4 x 5

IR3831MTRPBF

功能描述:直流/直流开关调节器 8A SupIRBuck Reg 250-1500kHz, 1.5-16V

RoHS:否 制造商:International Rectifier 最大输入电压:21 V 开关频率:1.5 MHz 输出电压:0.5 V to 0.86 V 输出电流:4 A 输出端数量: 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:PQFN 4 x 5

IR3831WMPBF

制造商:IRF 制造商全称:International Rectifier 功能描述:HIGHLY EFFICIENT INTEGRATED SYNCHRONOUS BUCK REGULATOR FOR DDR APPLICATIONS

IR3831WMPBF_1

制造商:IRF 制造商全称:International Rectifier 功能描述:HIGHLY EFFICIENT INTEGRATED SYNCHRONOUS BUCK REGULATOR FOR DDR APPLICATIONS

IR3831WMPBF_11

制造商:IRF 制造商全称:International Rectifier 功能描述:HIGHLY EFFICIENT INTEGRATED SYNCHRONOUS BUCK REGULATOR FOR DDR APPLICATIONS

IR3831WMTR1PBF

功能描述:直流/直流开关调节器 8A SupIRBuck Reg 250-1500kHz, 1.5-16V

RoHS:否 制造商:International Rectifier 最大输入电压:21 V 开关频率:1.5 MHz 输出电压:0.5 V to 0.86 V 输出电流:4 A 输出端数量: 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:PQFN 4 x 5

IR3831WMTRPBF

功能描述:直流/直流开关调节器 8A SupIRBuck Reg 250-1500kHz, 1.5-16V

RoHS:否 制造商:International Rectifier 最大输入电压:21 V 开关频率:1.5 MHz 输出电压:0.5 V to 0.86 V 输出电流:4 A 输出端数量: 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:PQFN 4 x 5